Choosing the right industrial air compressor installation service can significantly impact your facility’s efficiency and reliability. This guide highlights leading providers, examines key selection criteria, and offers critical tips to ensure a seamless installation process. Understanding what sets top companies apart helps you make informed decisions, ultimately securing optimal performance and long-term value for your investment.

Leading Industrial Air Compressor Installation Service Providers

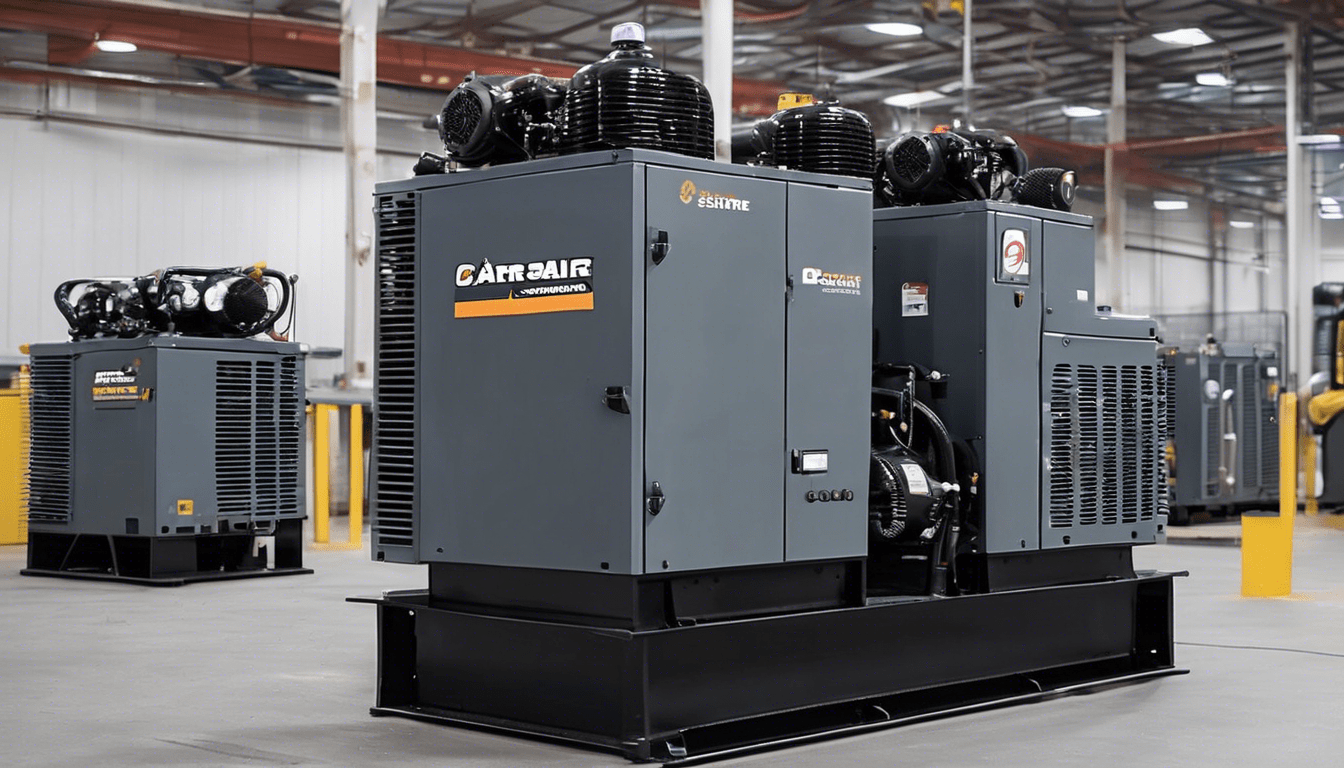

When considering industrial air compressor installation, choosing the right service provider is crucial for ensuring efficient and safe system operation. The most reputable companies in this sector combine extensive technical expertise, certified technicians, and a strong track record of successful installations. These providers often specialize in both the installation and maintenance of compressors, aligning their services with customer needs across various industries.

Also to read : Transform your outdoors with expert landscape design services

Selection criteria for top service providers typically include factors such as experience with different compressor models, compliance with industry standards, and responsiveness to client requirements. Additionally, providers offering comprehensive post-installation support further distinguish themselves, ensuring ongoing system reliability.

Regional and national coverage also plays a significant role in selecting a provider. Many leading companies maintain extensive service networks that allow them to handle installations across multiple locations efficiently. This geographical flexibility supports businesses with large-scale or multi-site operations, guaranteeing consistent service quality. For those seeking guidance on this topic, expert advice on industrial air compressor installation can clarify specific needs and options, facilitating better decision-making.

In parallel : Brighten your home: explore innovative flat rooflights

Key Factors to Consider When Choosing an Installation Service

Making the right choice for industrial air compressor installation is crucial for optimal performance and longevity.

Experience and Industry Certification

When selecting a service for industrial air compressor installation, prioritize providers with extensive experience and industry certifications. Experienced installers demonstrate a proven track record in handling complex systems, ensuring installations comply with safety standards, and optimizing equipment operation. Certifications from recognized industry bodies reassure that technicians are trained in the latest procedures and technologies relevant to air compressor systems. This level of expertise reduces the risk of errors during installation, which can lead to costly downtime or repairs.

Service Range and Response Time

The service range and response time of an installation provider directly impact your operation’s continuity. Choosing a company offering comprehensive installation services—including site assessment, system setup, and post-installation testing—ensures a smooth, end-to-end process. Additionally, a provider with a fast response time can address urgent installation needs or troubleshoot issues promptly, minimizing downtime. For industries where productivity depends heavily on compressed air systems, such timely service support is invaluable.

Customer Reviews and Satisfaction Ratings

Customer feedback provides insight into the reliability and professionalism of installation services. High customer satisfaction ratings and positive reviews reflect consistent quality, clear communication, and effective problem-solving during industrial air compressor installation projects. When evaluating providers, consider those with testimonials highlighting their adherence to schedules, technical knowledge, and thoroughness. These factors build confidence that the chosen installer will meet or exceed your expectations.

Cost Estimates and Service Packages

Transparent and competitive cost estimates are essential when planning for industrial air compressor installation. Reliable providers offer clear pricing structures and flexible service packages tailored to different industrial needs. Evaluate quotes to ensure they include all necessary components such as equipment handling, installation labor, and any additional services like maintenance. Avoid choosing solely based on the lowest bid; instead, balance cost with quality and provider reputation to achieve the best value and long-term performance.

Profiles of Top-rated Industrial Air Compressor Installation Companies

When evaluating industrial air compressor installation companies, key aspects include experience, certifications, customer service, and pricing. Understanding these factors helps businesses select a provider that aligns with their operational demands.

Company A stands out due to its extensive experience and positive client testimonials. With a broad service area, they have successfully handled installations in multiple industries, demonstrating adaptability and reliability. Clients frequently praise their prompt response times and professional project management, which ensures installations are completed efficiently.

In contrast, Company B brings a strong focus on certifications and specialized installations. Their teams are certified in handling complex compressor systems, which is particularly valuable for companies requiring tailored setups. Pricing here reflects the high level of expertise provided, often justified by the company’s ability to customize solutions and manage intricate technical requirements.

Meanwhile, Company C is recognized for exceptional customer support and comprehensive maintenance options. This company cultivates a reputation for ongoing service beyond installation, offering maintenance plans that enhance compressor longevity and performance. Their industry reputation is built on responsiveness and a commitment to reducing downtime through preventive servicing.

In summary, selecting the right partner for industrial air compressor installation depends on your specific priorities: whether it’s extensive experience, certified technical expertise, or strong customer support with maintenance services. Exploring these profiles provides a clear framework for making an informed decision tailored to your facility’s needs.

Service Features and Additional Offerings

When considering industrial air compressor installation, tailored solutions stand out as a crucial aspect. Customized installation solutions ensure that each compressor system is configured precisely to the specific operational needs of the facility. This approach enhances efficiency, reduces downtime, and aligns with production demands.

Post-installation support and maintenance form another vital feature. After the installation, ongoing maintenance services help preserve the longevity of the equipment and maintain optimal performance. Regular check-ups, lubrication, and system diagnostics prevent unexpected failures. This continuous support safeguards your investment, ensuring the compressors run smoothly over time.

Emergency response capabilities provide an essential safety net. Should any urgent issues arise with the compressor systems, rapid intervention minimizes disruption and averts costly production halts. Companies offering industrial air compressor installation often guarantee quick turnaround times to diagnose and repair problems promptly, underscoring their commitment to operational reliability.

In summary, selecting a provider for industrial air compressor installation should involve evaluating their ability to deliver customized installations, comprehensive maintenance services, and reliable emergency support. Together, these features enable a seamless, worry-free experience for industries reliant on compressed air systems.

How to Evaluate and Select the Best Service Provider

When choosing the right service provider for your industrial air compressor installation, it is crucial to assess several key factors to ensure reliable and professional results. Start by evaluating the provider’s credentials and industry experience. Look for companies with a proven track record in installing and maintaining industrial air compressors, as this experience directly translates into quality and efficiency on site.

Reviewing case studies and project portfolios offers valuable insight into the provider’s range and scope of completed jobs. This helps confirm whether their expertise matches your specific industrial requirements. Additionally, verifying that the service provider holds the proper licensing and insurance requirements provides peace of mind and protection against liabilities.

Requesting detailed comprehensive quotes and service agreements is another essential step. Make sure the quote outlines every aspect of the installation process, including timelines, equipment specifications, and post-installation support. A transparent service agreement prevents unexpected costs and clarifies responsibilities.

By systematically checking these elements—credentials, experience, licenses, and clear agreements—you can confidently select the best partner for your industrial air compressor installation needs. For an expert approach, consider exploring further details on industrial air compressor installation provided by specialists in the field.

Tips for Ensuring Successful Industrial Air Compressor Installation

Installing an industrial air compressor requires careful preparation and attention to detail to ensure optimal performance and longevity. A pre-installation site assessment is critical. This involves evaluating the available space, ventilation, and power supply to guarantee the location meets the compressor’s specifications. Without this step, you risk complications like inadequate airflow or electrical issues that can hinder the equipment’s efficiency.

Clear communication of operational requirements between the installation team and the plant management is another cornerstone of a successful industrial air compressor installation. Understanding the expected workload, pressure demands, and duty cycles informs the selection and setup of the compressor, ensuring it aligns with operational needs.

Synchronization of the installation with the plant’s production schedule is essential. Scheduling in alignment with plant operations minimizes disruption and downtime, preserving productivity while allowing installation teams to work safely and effectively.

Safety protocols during installation cannot be overstated. Implementing comprehensive safety measures, such as isolating electrical sources and using proper personal protective equipment, protects both personnel and machinery. These protocols should follow industry standards and be communicated clearly to all involved.

Choosing the Right Industrial Air Compressor

Selecting the appropriate industrial air compressor requires understanding your facility’s specific needs and operational demands. The key factors to consider include the compressor type, capacity, efficiency, and maintenance requirements.

Industrial air compressors generally fall into two main categories: reciprocating compressors and rotary compressors. Reciprocating compressors are suitable for smaller-scale applications or intermittent use, as they operate by pistons compressing air in cylinders. Rotary compressors, including screw compressors, are ideal for continuous, large-volume applications owing to their design that allows for steady airflow and greater efficiency.

Capacity, often measured in cubic feet per minute (CFM), must align with the air demand of your equipment. To determine the right capacity, calculate the total air consumption of all tools and machines that will run simultaneously. Selecting a compressor with insufficient capacity causes pressure drops and operational inefficiencies, while oversizing leads to increased energy costs.

Efficiency is another critical aspect more efficient compressors minimize energy consumption and operating costs. Look for models with variable speed drives, which adjust compressor output to match demand, reducing wasted energy.

Maintenance plays a significant role in compressor longevity and performance. Consider compressors with accessible parts and straightforward servicing protocols. Regular maintenance checks ensure your compressor runs smoothly and prevents unexpected downtime.

For those new to this process, consulting a professional service specializing in industrial air compressor installation will help tailor the choice to your operational environment. These experts assess your specific needs, provide installation guidance, and ensure adherence to safety standards.

Understanding these factors equips you to make an informed decision, maximizing your facility’s productivity while controlling costs. When selecting an industrial air compressor, always consider how it matches your workflow, maintenance capacity, and long-term efficiency goals.